When you hear “carbon fiber,” what comes to mind? Perhaps you imagine sleek, luxury sports cars or cutting-edge aerospace technology, both of which utilize the unique properties of this remarkable material. But today, let’s dive deeper into the nitty-gritty of carbon fiber: specifying the richness of **2 layers of 3K cloth** and the perplexing nature of thickness. Why is thickness such a critical factor in the realm of carbon fiber? And can understanding it pose a challenge for designers and engineers alike? Let’s embark on this intricate journey through carbon fiber clarity.

What is 3K Cloth?

Before we jump into the details of thickness, let’s clarify what 3K cloth actually is. The term “3K” refers to the number of carbon fibers in a single strand. Specifically, in 3K cloth, there are 3,000 individual filaments woven together. This results in a fabric that boasts a perfect blend of strength and flexibility, making it an ideal choice for various applications, from automotive parts to sporting goods.

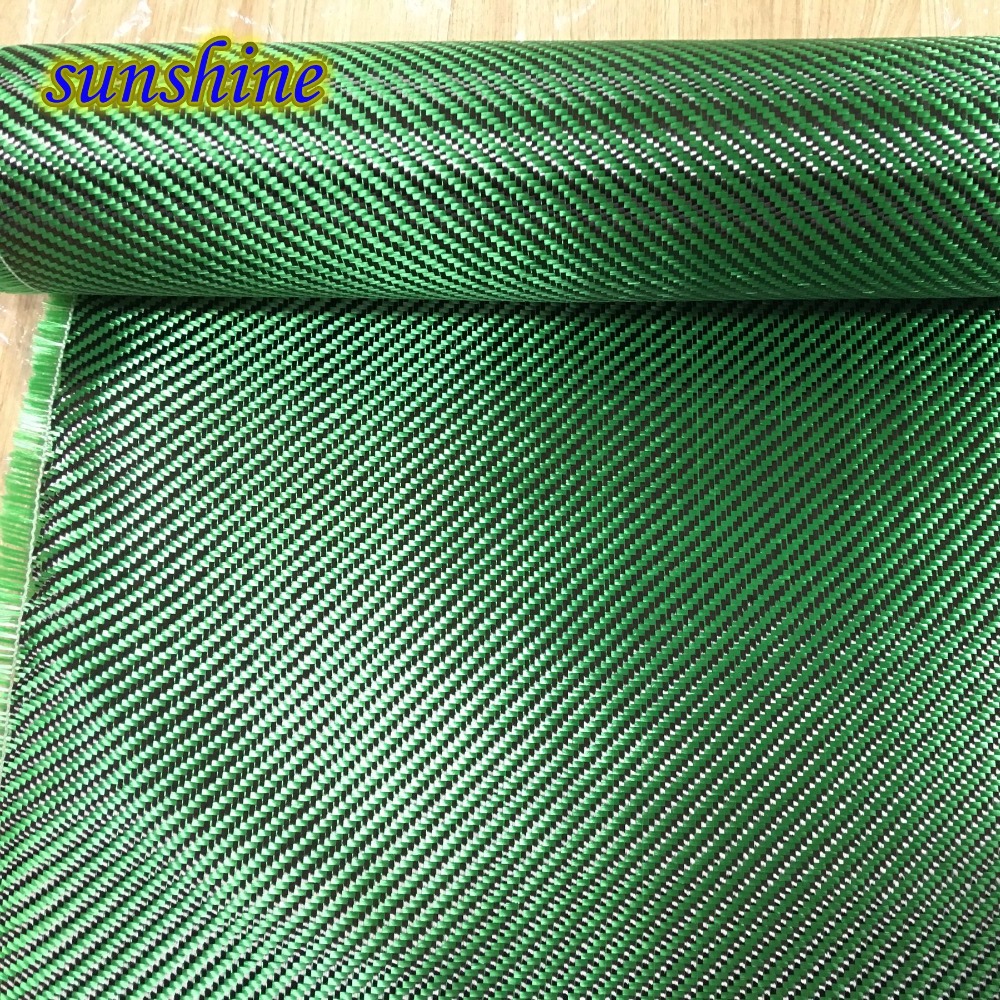

The **unique weaving technique** used in manufacturing 3K cloth contributes to its overall performance. The fabric has a distinct appearance, often characterized by its tight weave and light-catching sheen. This not only appeals to aesthetic sensibilities but also reflects the material’s engineering quality. But what lies beneath this visual appeal? That’s where we address the matter of thickness.

The Enigma of Thickness

Thickness is a term often tossed around in materials science, yet its implications are rarely adequately understood. The thickness of a carbon fiber layer can significantly influence its **mechanical properties**, including tensile strength, stiffness, and durability. For 3K carbon fiber cloth, each layer’s thickness will determine how the material behaves under various conditions.

When layering multiple sheets, such as in our case with **two layers of 3K cloth**, the cumulative thickness can produce a stronger composite material. However, there’s an equally important aspect to consider—weight. Increasing the number of layers may enhance strength but could also introduce weight concerns, especially in applications where minimizing mass is critical. Thus, one must ask: how do we strike the perfect balance between strength and weight?

Understanding Layer Interactions

When you place two layers of 3K cloth on top of each other, the interaction between the layers can lead to different outcomes than if they were applied individually. At this juncture, the question of **stacking orientation** arises—are the fibers aligned in the same direction or crisscrossed? The method of layering can fundamentally alter the material’s rigidity and ductility.

For example, when fibers are aligned, they will resist tension forces better, serving effectively in applications like ties or structural beams. Alternatively, when crisscrossed, the composite may experience different stress responses, such as enhanced shear strength, making it more suited for load-bearing applications.

This brings us to the pivotal inquiry—how do designers determine the optimal configuration for their specific application? This is where creativity meets science and where an understanding of carbon fiber’s properties becomes paramount.

The Role of Resin

No discussion of carbon fiber composites would be complete without mentioning resin. The choice and application of resin play a crucial role in determining the final properties of the layered materials. The resin not only acts as a bonding agent that holds the layers together but also helps to influence the overall thickness.

For instance, a thicker layer of resin between the 3K cloth can enhance the durability but can also ultimately lead to a heavier end product. Moreover, various types of resin (epoxy, vinyl ester, or phenolic) come with their distinct advantages and disadvantages regarding temperature resistance and curing times. The interplay between fiber thickness, resin application, and overall performance presents an ongoing challenge for engineers and designers striving for excellence.

Applications and Implications

So, where do all of these considerations lead us in practical terms? Let’s explore some captivating applications of two layers of 3K cloth. In the automotive industry, for instance, using this material in both aesthetic parts, like body kits, and functional components, such as chassis reinforcements, showcases the dual appeal of carbon fiber.

While sports equipment, from bicycles to surfboards, benefits from increased performance and reduced weight, the implications extend to aerospace engineering where safety and reliability are crucial. The combination of diligence in application design and meticulous attention to the material’s attributes provides the potential for innovation, albeit accompanied by challenges relating to cost and complexity.

Conclusion: The Navigator’s Journey

In conclusion, achieving clarity in carbon fiber is no small feat. With thickness, layering, material properties, and applications all clashing and converging, understanding this complex interplay demands both technical expertise and creative thinking. As you contemplate your next project involving carbon fiber, the task is not just to harness its extraordinary properties but to navigate the intricate relationships between material choices. In doing so, one unlocks a realm of possibilities as vast as the sky above—limited only by imagination and ingenuity.

So, what challenges will you face as you incorporate carbon fiber into your creations? The answer lies in your adventurous spirit as you journey through this fascinating medium.