The ignition system is an integral component of any internal combustion engine, functioning as the catalyst that ensures proper combustion of the air-fuel mixture. A critical element within this system is the distributor coil, also known as the ignition coil. With a remarkable capability to transform low-voltage battery power into the high voltage required to initiate combustion, understanding how to test this component can lead to improved vehicle performance and longevity.

First and foremost, one must familiarize themselves with the ignition coil’s basic mechanics. It operates by inducing a magnetic field through two wire windings: the primary winding, which receives a low-voltage current, and the secondary winding, which converts this current into a high-voltage discharge. This electrical surge travels through the ignition wires to the spark plug, resulting in the ignition of the fuel-air mixture within your engine’s cylinders.

Many car enthusiasts often overlook the significance of the ignition coil until problems arise. Symptoms of failing ignition coils can manifest in various forms: poor engine performance, difficulty starting, rough idling, or a noticeable decrease in acceleration. Consequently, understanding how to test a distributor coil becomes pivotal for anyone wishing to maintain their vehicle in optimal condition.

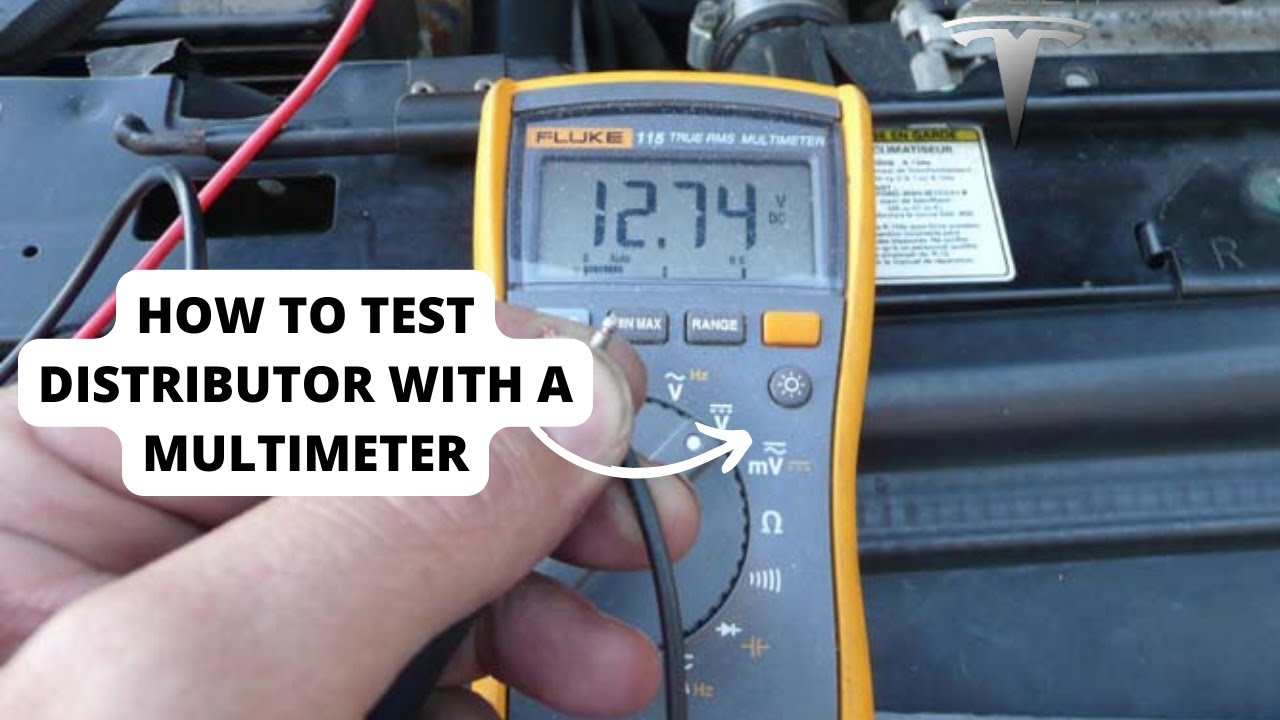

To begin testing, one must first prepare adequately. Ensure that the vehicle is turned off and the keys are removed from the ignition. Safety should always be the priority; thus, wearing protective gear such as gloves and safety goggles is advisable. With a few necessary tools—an ohmmeter or multimeter, and perhaps a basic socket set—you will be ready to delve into the intricacies of coil testing.

Start by locating the ignition coil, which is typically situated near the distributor cap. In some vehicles, it may be mounted on the engine block itself. Upon visual inspection, look for any obvious signs of wear, such as cracks, corrosion, or burnt contacts. These visual cues can often provide early warnings of impending coil failure.

With the ignition coil accessible, the next step involves electrical testing. Begin with a resistance test using an ohmmeter. Disconnect the ignition coil from the engine harness to isolate it for an accurate measurement. Set your multimeter to the ohms setting and measure the resistance across the primary terminal and ground. A typical resistance reading should generally fall within the range specified in your vehicle’s service manual—most often between 0.5 to 2.0 ohms. If your measurements exceed this range, the coil may be faulty.

Next, proceed to the secondary winding test. Connect the multimeter leads to the secondary terminal and ground, which usually yields a significantly higher resistance than the primary winding. Again, refer to the service manual for the exact specifications, as acceptable readings can vary widely depending on the ignition system design—often ranging from 6,000 to 15,000 ohms. Deviations from these values can be indicative of an aging or damaged coil.

Once the resistance testing is concluded, you might feel tempted to jump into quick conclusions, yet it is imperative to consider the coil’s performance under operational conditions. In many cases, coils can pass resistance tests while continuing to underperform when subjected to real-world conditions—symptomatic of breakdowns occurring under heat or load. A thorough bench test may be necessary if symptoms persist.

Now, while the method of testing a distributor coil may induce a mix of fascination and apprehension, it effortlessly encapsulates the essence of automotive engineering. As you engage with your vehicle’s intricacies, you gain not just knowledge but also an appreciation for the artistry involved in modern-day vehicle manufacturing.

However, should your testing reveal that the ignition coil is operational, yet other symptoms persist, it is wise to consider the broader ignition system. Worn spark plugs, malfunctioning ignition wires, or even issues within the electronic control unit may contribute to your vehicle’s lackluster performance. In such instances, a comprehensive diagnostic evaluation becomes crucial.

In the realm of automotive maintenance, the coil may be a small component, but it plays a monumental role within the ignition system. By mastering the art of testing a distributor coil, you cultivate not just a relationship with your vehicle, but also an understanding that deepens your interaction with automotive mechanics in general. Each task, whether simple or complex, stitches together a narrative of how systems operate in harmony, driven by the power of combustion.

Remember, knowledge serves as both a tool and a treasure; handling your vehicle’s ignition system with confidence can lead to not only smoother drives but also a greater appreciation for the intricate dance of engineering. So the next time your engine misfires or your acceleration lags, you’ll know exactly where to turn your attention. With this newfound understanding, you’ll delve deeper into the world of automotive care—where each turn of a wrench can spark not only knowledge but also the joy of tinkering.