In the vast universe of automotive and electrical maintenance, dielectric grease emerges as a hero—an unsung champion in the battle against moisture, corrosion, and the wear-and-tear of electrical connections. While many may overlook this utilitarian substance, the reality is that dielectric grease has the potential to revolutionize how we approach maintenance and ensure optimal performance in numerous applications. But what exactly does dielectric grease do, and when should you utilize it? Let’s traverse the intricacies of this fascinating compound.

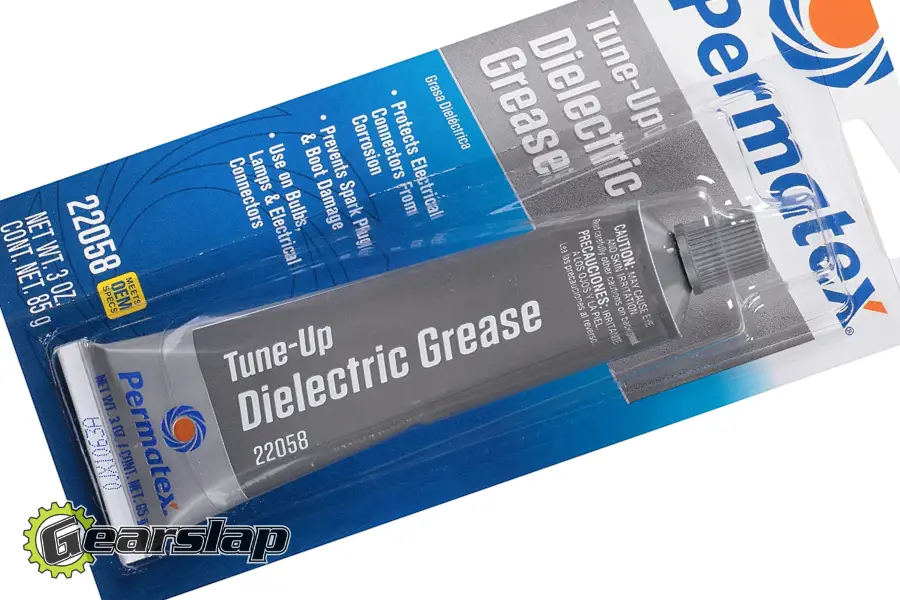

At its core, dielectric grease is a silicone-based compound designed to be non-conductive. This fundamental characteristic separates it from typical greases, which often conduct electricity. While you might think that grease and electronics don’t mix, dielectric grease is akin to a protective shield, not merely a lubricant. It fills the gaps in electrical connectors, providing a waterproof barrier that wards off moisture and dust, both of which are notorious for contributing to electrical failures.

A pivotal intrigue revolves around the name itself: “dielectric.” This term refers to materials that are insulators, meaning they do not conduct electricity. The very purpose of dielectric grease is to insulate and protect critical components. Interestingly enough, it does not just prevent issues; it prolongs the life of your electrical connections. Over time, oxidation can degrade many connectors, leading to frustrating malfunctions. With the application of dielectric grease, you are actively counteracting this corrosive tendency.

In essence, dielectric grease should be a go-to in various scenarios. Picture this: automotive projects or DIY electrical repairs demand that you work with a myriad of connections, from spark plugs to circuit boards. Here, dielectric grease is invaluable. It acts as a guardian, surrounding connectors with a soft, flexible barrier that ensures moisture does not penetrate into vulnerable areas. Often, a simple application of this grease can avert disastrous failures that could otherwise manifest in inconvenience or costly repairs.

One of the most common applications for dielectric grease lies in automotive maintenance. Here, the exposure to extreme conditions—the scorching heat of an engine or the torrential downpours during a rainstorm—plays a vital role in the degradation of electrical components. For instance, when securing a spark plug, a thin layer of dielectric grease can prevent ignition issues caused by moisture encroaching into the connection. Think of it as giving each connection a raincoat, providing that essential barrier without obstructing the electrical flow. And yes, it is safe to use even on rubber components, making it a versatile ally.

Moreover, the realm of household electronics is not exempt from dielectric grease’s protective embrace. Television and computer connections are notoriously susceptible to dust and moisture. A periodic application of this grease on HDMI ports, RCA connectors, and other vital junctions ensures unimpeded signal flow. Imagine operating your home theater system without the nagging fear of static interference or signal degradation! The peace of mind this simple tool provides truly feeds the spirit of innovation in maintenance culture.

However, let us not forget that while dielectric grease is a formidable guardian, it does not serve every situation. For instance, uses involving high-voltage connections may warrant caution, as the thickness of the grease may interfere with the connection’s integrity. In these cases, it would be prudent to consult specific guidelines to ensure optimal safety and performance. Additionally, users should avoid over-application; a little goes a long way, and excessive grease can effectively act as a magnet for dirt, counteracting its protective purpose.

The allure of dielectric grease often lies in its versatility across various applications, but have you considered the implications of using it in non-electric scenarios? Canoeing enthusiasts can leverage dielectric grease for zippers, which notoriously fail when they encounter moisture. Additionally, gardening aficionados have found success in protecting metal tools from rust via a light coat of this silicone-based grease. The imaginative usages are virtually limitless!

It is also prudent to understand that dielectric grease is not a universal solution. Assessing the specific type of lubricant required for any given application is crucial. In certain circumstances, such as with bearings or moving mechanical parts, a standard lubricant may be more appropriate. Yet, this nuanced understanding makes dielectric grease a must-have for all enthusiasts, hobbyists, and professionals alike. Its place in the toolkit is no longer merely an afterthought.

In conclusion, dielectric grease embodies a fusion of protective efficacy and adaptability. Rather than simply dismissing it as a curio for electrical engineers, one should view this compound through a more profound lens. The investment in dielectric grease is an investment in longevity, ensuring that the connections we rely on every day remain protected against the ravages of time and nature. As we embrace a more comprehensive understanding of dielectric grease, let it prompt us to reconsider how we maintain our tools, appliances, and vehicles. From automotive mechanics to home improvement projects, let the incorporation of dielectric grease transform the way you think about maintenance. The next time you reach for that tube, recognize it as more than just a grease—see it as an essential guardian in the vast landscape of connectivity and performance.