When it comes to air compressors, the air chuck is often an overlooked component in the grand machinery of pneumatic tools. Yet, this seemingly simple piece of equipment is essential for maximizing the efficiency and versatility of your air compressor system. Delve into the world of air tool essentials, and you’ll discover that choosing the right air chuck can dramatically enhance your experience while minimizing headaches on the job.

To start, let’s untangle the basics. An air chuck, often referred to as a tire chuck, is a device that connects to the end of an air hose, facilitating the transfer of air into various objects—most commonly tires. However, the applications extend far beyond mere inflation; whether you are a dedicated DIY enthusiast, an automotive professional, or an occasional user, selecting the best air chuck makes all the difference.

### Understanding Air Chucks: Types and Mechanisms

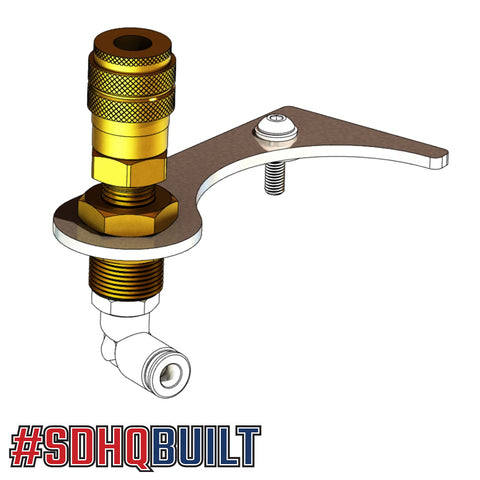

The diverse landscape of air chucks can be categorized primarily into two types: **manual chucks** and **automatic chucks**. Both possess unique characteristics, tailored to different kinds of tasks. Manual chucks, as the name suggests, require the user to engage them physically. They boast simplicity and reliability, making them a go-to choice for home mechanics. Their leverage mechanism typically includes a lever that you push to lock and unlock the connection to your valve.

On the other hand, automatic chucks—often designed with a quick-release mechanism—are ingeniously engineered for efficiency. These are particularly advantageous in high-paced environments; they engage automatically upon connecting to a tire valve or other objects. Imagine the hustle and bustle of a busy workshop, where every second counts; an automatic chuck can save time and streamline processes amidst the flurry of activity.

### Features and Specifications to Consider

Now that we’ve examined the types, let’s delve deeper into the core features that differentiate the myriad options available in the market today. First and foremost, keep an eye on the **construction material**. Most chucks are crafted from alloys or robust plastics. Metal versions tend to offer enhanced durability, while plastics can be more lightweight—an important consideration for ease of use during prolonged tasks.

Next, gauge the **threading dimensions** of the air chuck. The most common sizes include ¼ inch and ½ inch NPT (National Pipe Thread). Ensuring compatibility with your air compressor is crucial to avoid any incompatibilities that would obstruct your workflow.

The **air flow rate** is another pivotal specification. For optimal performance, your chosen chuck should complement the flow rate output of your compressor. Failure to match these specifications can lead to inefficient air delivery, underperformance, and could potentially damage your tools over time.

What about the **design**? While practicality reigns supreme, aesthetics can also play a role. Some manufacturers offer air chucks with ergonomic features, such as rubber grips, which can significantly enhance user comfort and dexterity during use. Investing in a chuck that feels right in your hand will transform tedious tasks into more enjoyable experiences.

### The Perfect Fit: Finding Your Ideal Air Chuck

As you gear up to make a decision, consider not only the type and specifications of the air chuck but also the intended applications. If you primarily work on automotive projects, a robust professional-grade chuck that can handle high PSI (pounds per square inch) is paramount. Meanwhile, for more casual uses, such as inflating sports equipment or air mattresses, a simpler and less-expensive option may suffice.

### Using Your Air Chuck Effectively

Once you’ve acquired your ideal air chuck, mastering its use is essential. Start by ensuring a secure fit with your hose and proper orientation towards the valve. A proper seal is key to preventing air leaks; these pesky leaks can sabotage your efficiency and inflate your working time. It’s often recommended to examine the rubber O-rings or seals frequently, as they may wear down and require replacement to maintain optimal performance.

When engaging with your chuck, employing a slow, steady action can yield better results than a rushed approach. Patience pays off here, regardless of whether you’re inflating tires or operating pneumatic tools. Establish a habit of checking the gauge after each connection to avoid under- or over-inflation—both can lead to significant repercussions for your equipment and safety.

### Maintenance Tips for Longevity

To elongate the lifespan of your air chuck and keep it performing at its best, a bit of maintenance goes a long way. Regularly clean the chuck to avoid a build-up of dust and debris that can lead to malfunction. Consider applying a few drops of lubricant on the moving mechanisms to facilitate effortless engagement and disengagement. Store your air chuck in a dry environment to discourage corrosion or deterioration of materials. Simple daily practices can save you from costly replacements down the line.

### Conclusion: Elevate Your Air Compressor Experience

In conclusion, navigating the realm of air tools isn’t just about functionality; it’s about choice, preference, and adaptability. As you embark on your journey to find the perfect air chuck for your air compressor, keep in mind the various types, essential features, and appropriate applications. This small yet significant piece of equipment can revolutionize your strategy in managing tasks efficiently and effectively. Remember, the benefits of a well-chosen air chuck stretch far beyond inflation—they extend to the enhanced performance of all your air-operated tools. Elevate your air compressor experience and empower your tasks with the right air chuck today!