When you think about metals, what comes to mind? Perhaps you envision the robust strength of steel, the shiny allure of gold, or even the lightness of aluminum. But have you ever pondered the concept of density, particularly how it relates to aluminum? Density may seem like an abstract concept, but it forms the cornerstone of various applications across industries. Today, let’s explore the density of aluminum in g/mL, its standard value, and the multifaceted applications that arise from this seemingly innocuous yet crucial property.

To kick things off, what exactly is density? In simple terms, density is the measure of mass per unit volume. Mathematically, it is expressed as:

Density (ρ) = Mass (m) / Volume (V)

This ratio allows us to differentiate materials based on how much “stuff” is packed into a given space. Now, let’s focus on aluminum, a material that has become a staple in the modern world.

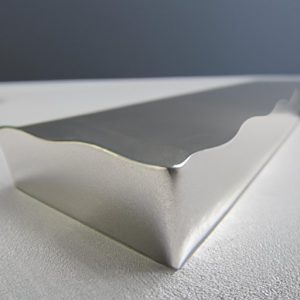

The standard density of aluminum is approximately 2.70 g/mL. This value is significant when we consider the implications it brings to various fields, from aerospace to packaging. Aluminum is prized for its lightweight nature combined with strength, making it an ideal choice for applications requiring materials that do not overly burden structures or equipment.

Now, imagine you’re tasked with designing a lightweight aircraft. Given aluminum’s standard density, it presents a conundrum: how can you maximize the benefits of aluminum while minimizing any potential drawbacks, such as susceptibility to corrosive elements? This challenge prompts ingenuity and innovation in material science. It also begs the question: what properties of aluminum make it such a versatile material in various sectors?

One of aluminum’s most commendable attributes is its malleability. Unlike many metals that crack under pressure, aluminum can be bent and shaped into various forms without losing structural integrity. This characteristic, paired with its lower density, leads to substantial energy savings in transport, production, and other applications. For instance, in the aerospace industry, engineers create airframes that harness aluminum’s combination of strength-to-weight ratio, leading to more fuel-efficient flying.

But wait, it doesn’t stop there! Aluminum also boasts excellent corrosion resistance, which can be attributed to its natural oxide layer. This layer forms almost instantly when aluminum is exposed to oxygen, creating a protective barrier that increases longevity and robustness. This intrinsic property is especially beneficial in marine applications, where materials are constantly at the mercy of saltwater and moisture.

Let’s pivot to another captivating realm: packaging. The food and beverage industry revels in aluminum’s lightweight properties, as containers made from aluminum reduce transportation costs and increase product shelf life. The recyclable nature of aluminum signifies its role in promoting sustainability; by recycling aluminum, up to 95% of the energy required to create new aluminum can be conserved. It’s a win-win scenario for companies and the environment alike!

Furthermore, the unique thermal conductivity of aluminum makes it an ideal candidate for heat exchangers and cooking utensils. Its ability to distribute heat evenly ensures that food cooks uniformly, making it a favorite among culinary enthusiasts. But here’s a fun challenge: how does one strike the perfect balance between weight and performance in designing cookware? The answer may lie in understanding density and how it impacts cooking efficiency.

Now that we’ve traversed through some captivating applications of aluminum let’s unravel the process behind determining its density. Various techniques can be employed, including Archimedes’ principle, which utilizes displacement to measure volume. By submerging aluminum in a liquid and observing the displaced volume, you can calculate its density. This method, while simple, beautifully illustrates the relationship between density and buoyancy. Can you think of any other materials that might present challenges when assessing their density using similar methods?

Moreover, the density of aluminum can fluctuate slightly based on its alloy composition. Different alloys can manipulate the density based on the proportion of aluminum relative to other metals. This variability opens a Pandora’s box of possibilities for engineers and designers. In creating custom alloys, one can adjust strength, malleability, and even resistance to heat or corrosion. It’s intriguing to think how subtle changes in composition can yield vastly different material behaviors!

In conclusion, the density of aluminum, with its standard value of 2.70 g/mL, serves as a fundamental element that underscores its vast utility in a myriad of applications. From aircraft to food packaging, and from cookware to structural components, the interplay between aluminum’s density and its unique properties fosters innovation and exceptional design. As industries continue to rely on aluminum, understanding its density and implications becomes crucial in meeting the ever-evolving needs of technology and sustainability. So the next time you encounter aluminum, take a moment to appreciate the science behind its density—and perhaps even consider the myriad ways in which it shapes the world around us.