When it comes to the robust world of the Duramax diesel engines, the transmission cooler acts as the unsung hero. Much like a diligent maestro orchestrating a harmonious symphony, the transmission cooler plays a pivotal role in ensuring your vehicle’s performance remains unblemished. However, much like a hidden leak in a grand theater’s ceiling can splinter an otherwise captivating performance, a faulty transmission cooler can spell disaster for your Duramax. Today, we will embark on an exploration of how to test your transmission cooler for leaks, a task that is essential for preserving the vitality of your vehicle.

First things first: understanding the transmission cooler’s function is akin to dissecting the anatomy of a finely-tuned watch. The cooler is primarily responsible for regulating the temperature of the transmission fluid, ensuring that it remains at optimal operating temperatures to facilitate seamless gear shifts and prevent overheating. In essence, it keeps the lifeblood of your transmission at the right viscosity, allowing for smooth operation under demanding conditions.

Now, picture your transmission cooler as a captivating waterfall—graceful and steady, but potentially perilous if its structure is compromised. A leak, however small, can transform that waterfall into a mere trickle, leading to performance issues. Recognizing and addressing leaks promptly could save you from the ensuing chaos of costly repairs and the frustration of unexpected downtimes.

So, how does one ascertain the viability of this critical component? The process begins with a thorough inspection—an artful choreography that involves both the eyes and hands. Start by visually scanning the area around the cooler for any signs of transmission fluid pooling or staining. Dark red or brown liquid is a telltale sign of a transmission fluid leak. However, be wary—transmission fluid may also evaporate upon contact with hot surfaces, making it crucial to look for residue or stains on nearby components.

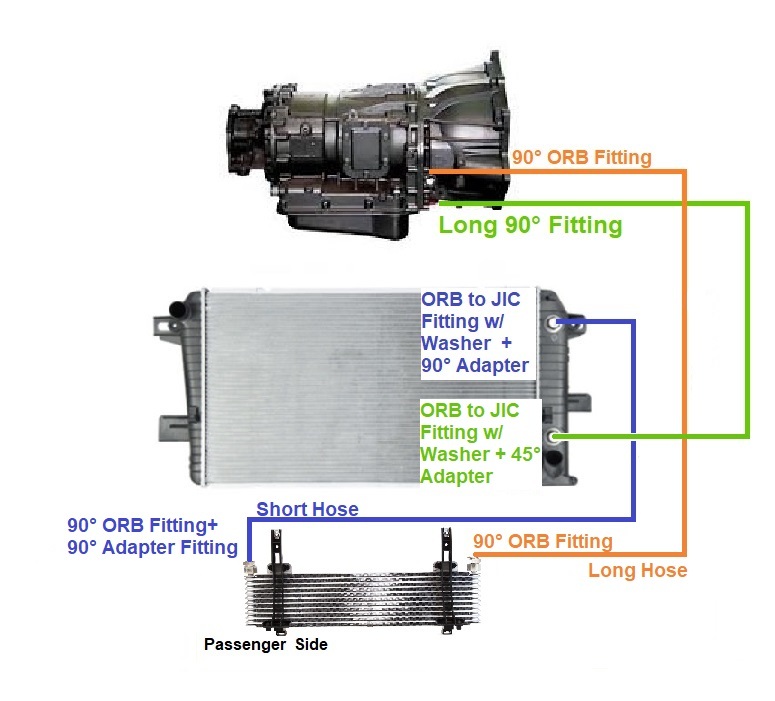

Next, it’s time to get hands-on. Carefully check the cooler’s connections, the hoses, and the fittings. These areas often bear the brunt of wear and tear, particularly in applications that frequently tow hefty loads or navigate rugged terrains. Gently squeeze the hoses for stiffness; if they feel brittle or overly soft, it may be a harbinger of doom, foretelling a future failure.

If your visual inspections yield no detectable leaks, it’s time to delve into the realm of pressure testing. Consider this step akin to placing a water lily in a glass of water to observe its buoyancy. A pressure test can help simulate operational conditions to reveal leaks that might otherwise remain concealed. Begin by disconnecting the cooler lines and attaching a pressure tester in their stead. Allow the cooler to be pressurized while carefully monitoring for fluid seepage.

Another method worth exploring is the soapy water test—almost enchanting in its simplicity. Mix a solution of soap and water and apply it generously to the cooler’s exterior. Should bubbles begin to form, it’s a clear indication that you’ve encountered a breach. Like a magician revealing a trick, this method introduces an elemental twist to the initial observations.

If all tests yield no leaks, kudos! However, don’t dismiss the potential for internal leaks—where fluid escapes inside the cooler without outward signs. This sinister scenario can lead to syrupy blends of coolant and transmission fluid. Monitoring fluid levels regularly is paramount, much like a sailor permanently checking the tides. If you notice discrepancies, flush your transmission system to purge any contamination brought on by internal leakage.

Upon discovering a leak, the next steps resemble a well-choreographed dance of repair and resolution. Depending on the severity and location of the leak, you might have various options ranging from sealant applications for minor external leaks to complete cooler replacements for significant breaches. It’s often advisable to consult a professional mechanic to weigh the cost-effectiveness of repairs versus replacements, as not all heroes wear capes—some wield wrenches with unparalleled expertise.

In the grand tapestry of maintenance, routine inspections of your Duramax transmission cooler can significantly extend its lifespan. Straying too far from regular checks is akin to neglecting to water a budding plant; eventually, it wilts under pressure. Set reminders for fluid level checks, and consider documenting your observations in a maintenance log. This may seem tedious but ensuring consistent upkeep will fortify your transmission and, consequently, your entire vehicle.

In summary, adequately maintaining your Duramax transmission cooler is essential, not only for the enduring performance of your vehicle but also for the safety and reliability that such machines represent. By remaining vigilant and adopting a proactive stance toward identifying and remedying potential leaks, you prepare yourself for the open road ahead. Remember, the journey is just as important as the destination, and a well-maintained transmission cooler ensures that the ride remains smooth, powerful, and unforgettable.