In the grand theater of maintenance and engineering, greases play the unsung roles, akin to the chorus dancers in a magnificent Broadway musical. Among the myriad performances, three leading contenders capture the spotlight: DC4 Grease, Dielectric Grease, and Silicone Grease. Each offers unique characteristics, providing distinct functionalities that cater to various applications in the intricate machinery of our lives. To appreciate their intricacies, we must take a promenade through their enchanting features, advantages, and ideal usages.

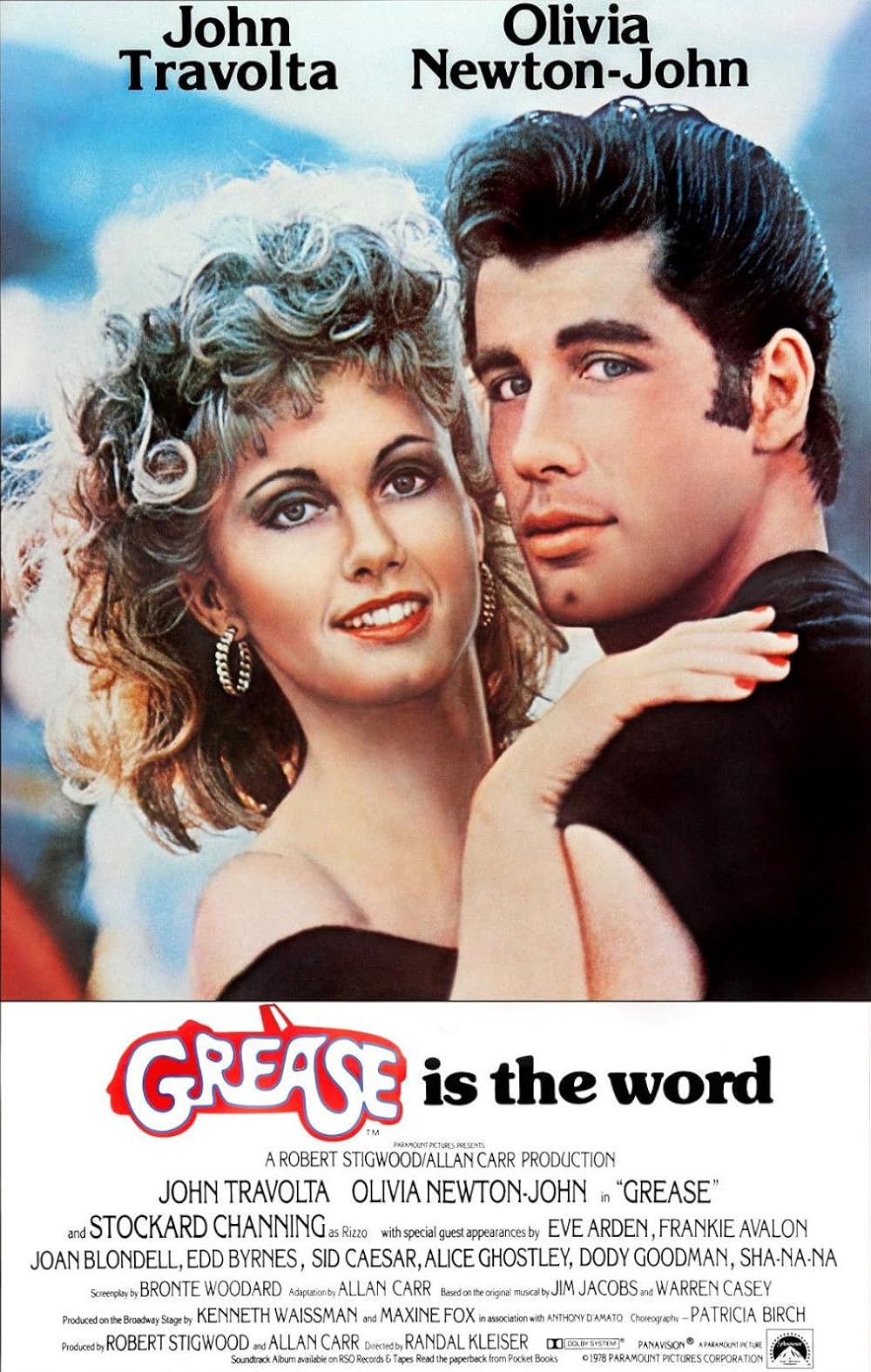

Let’s first unravel the curtain on DC4 Grease. This performer boasts a high-temperature, lithium-based formulation that thrives in challenging environments. It’s as if it’s donned its leather jacket, ready to take on the heat of a summer’s night at Rydell High. DC4 Grease is recognized for its remarkable resistance to thermal breakdown. This is crucial for applications where machinery may be subjected to elevated temperatures, enduring persistent friction akin to dancers twirling under hot stage lights. Applications include automotive fittings, bearings, and any mechanical assemblies demanding longevity and robustness.

What sets DC4 Grease apart is not solely its thermal resilience. It also exhibits excellent water resistance, creating a barrier against moisture that could corrode equipment. Imagine this grease like a valiant guardian—protective and vigilant against the encroaching elements. Its versatility allows it to operate effectively across a variety of materials, including metals and plastics, with a performance that remains consistent, even when the opera house is at full capacity.

Just as every Broadway show needs a contrast to captivate its audience, we find such a juxtaposition in Dielectric Grease, a superstar of electrical insulation. While DC4 excels in mechanical realms, Dielectric Grease takes center stage when it comes to protecting electrical connections. This non-conductive wonder is often used to shield against moisture and corrosion in electrical and electronic applications. Picture it as the shy but reliable friend who stands at the periphery of the spotlight, ensuring everything functions harmoniously behind the scenes.

Dielectric Grease is crafted from silicone compounds, embodying a silicone-derived versatility that allows it to endure extreme temperatures without succumbing to degradation. Its non-conductive nature makes it an invaluable asset in automotive and marine environments, acting as a conduit of protection that ensures electrical connections remain intact, much like ensuring a tightly-knit cast remains cohesive during a performance. Moreover, its capacity to repel water while maintaining its integrity under extreme conditions draws parallels to a seamless performance that is both captivating and resilient.

Every great performance also possesses an element of flair, and that’s where Silicone Grease takes its cue. This grease transcends the ordinary, offering a fascinating blend of properties that harmonize with various applications. Silicone Grease not only boasts excellent thermal stability and water resistance, but it also acts as a lubricant for a wide array of materials, from rubber seals to plastics, maintaining the beauty of these interactions. This is akin to an actor effortlessly transitioning from one role to another, adapting fluidly to the needs of each scene.

Silicone Grease is especially favored in situations where food safety is paramount, particularly in kitchen and laboratory environments. It serves as an unyielding protector—ensuring that seals on appliances and machinery not only function but thrive. This grease’s inert nature ensures that it remains unaffected by the substances it sometimes encounters, providing an unwavering performance that’s as reliable as a Broadway lead. Uniquely, its ability to endure extreme temperatures further cements its role as an indispensable player in the world of mechanical and electrical applications.

So, how do these greases compare when placed side-by-side? It can be likened to a fabulous trio of protagonists, each with their distinct flair. DC4 Grease, with its robust resistance to heat and wear, shines brightest in environments demanding sheer durability. Dielectric Grease, the unsung hero, thrives under electrical strain, keeping connections secure while warding off moisture. Meanwhile, Silicone Grease flits effortlessly between various roles, safeguarding seals and providing crucial lubrication across a vast array of applications.

As we piece together this grease toolkit, recognizing the unique characteristics of each formulation enhances our understanding of optimal use cases. The grease that might be ideal for your vehicle’s bearings (DC4 Grease) may not be suitable for electrical connectors (Dielectric Grease), and similarly, the grease used in a kitchen appliance (Silicone Grease) might differ vastly in application suitability. It is this attention to detail—this understanding of distinct roles—that enables us to achieve maximum performance with minimum hassle.

In conclusion, the essence of each grease is akin to a key character in a multi-faceted production: DC4 Grease is the dependable hero, Dielectric Grease serves as the protector, and Silicone Grease embodies versatility. Their synergistic interplay doesn’t merely grease the wheels of machinery; it orchestrates a seamless harmony that keeps everyday operations running smoothly. Adopting the right grease is pivotal in ensuring longevity—and just like the perfect cast in a musical, it creates an unforgettable performance, time after time.