In the intricate ballet of internal combustion engines, oxygen sensors serve as the attentive conductors, orchestrating the delicate balance between fuel and air. These sensors are pivotal in ensuring optimal engine performance, and understanding their functionality is akin to deciphering a cryptic language that speaks to the health of your vehicle. One of the most crucial aspects of this dialogue is the normal O2 sensor voltage at idle, a measurement that reveals essential insights into the engine’s efficiency and emissions control.

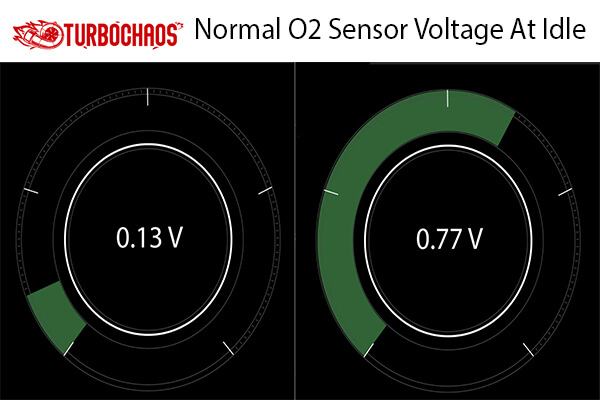

At first glance, the O2 sensor may appear to be a mundane component, yet at idle, it plays a role that is anything but trivial. Picture a quiet room filled with musicians tuning their instruments; this is akin to your engine at idle, where the O2 sensor provides real-time feedback to ensure harmony. The normal voltage output from an O2 sensor typically oscillates between 0.1 to 0.9 volts. This range signifies the sensor’s ability to relay varying concentrations of oxygen in the exhaust gases, reflecting the efficiency of the combustion process.

When the engine idles, it runs on a delicate mixture of air and fuel. Here, the O2 sensor becomes the vigilant eye, continuously monitoring the exhaust gases and communicating with the Engine Control Unit (ECU). The ECU, like a seasoned conductor, adjusts fuel delivery and ignition timing based on the data received from the O2 sensor. A reading that drifts far from the norm can be indicative of underlying issues such as a lean or rich mixture, potentially leading to performance problems or increased emissions.

But what causes these deviations in O2 sensor voltage? Various factors can play a role. For instance, a failing sensor may provide misleading readings, akin to a musician hitting the wrong notes. This could arise from contamination due to oil or fuel leaks, which can coat the sensor and hinder its performance. Alternatively, exhaust leaks can introduce unmeasured air into the exhaust stream, leading to an incorrect assessment of the air-fuel ratio.

A diagnostic tool can be invaluable in these situations, providing a window into the health of the oxygen sensor. Connecting a scan tool or multimeter allows you to gauge the voltage output while the engine is running at idle. By observing the voltage fluctuations, one can ascertain whether the sensor is functioning within its typical parameters. If the voltage remains static, or fails to fluctuate within the specified range, it may indicate a failing sensor or an issue elsewhere in the fuel delivery system.

Moreover, understanding the interplay between the O2 sensor and the vehicle’s climate control system is fundamental. Just as an artist adjusts their palette according to the ambient light, the ECU modulates the fuel mixture based on environmental conditions. Variations in temperature can affect sensor performance, and O2 sensors may produce different voltage outputs in cold versus warm conditions. Therefore, holistic diagnostics consider not only the sensor itself but also the larger system at play.

When interpreting O2 sensor readings, one must also take into account the type of sensor—particularly between narrowband and wideband O2 sensors. Narrowband sensors are primarily employed in older models, providing indications of rich or lean conditions without delivering exhaustive data. In contrast, wideband sensors, prevalent in modern vehicles, offer a more detailed analysis of the air-fuel mixture, allowing for finer tuning and improved fuel efficiency. The transition from narrowband to wideband sensors underscores the automotive industry’s evolution toward precision and efficiency, mirroring broader technological advancements.

Ensuring the proper function of the O2 sensor can yield immediate benefits, including improved fuel economy and reduced emissions. When the sensor operates within its expected voltage range at idle, it signals an effective combustion process, optimizing fuel usage and minimizing waste. This is akin to a well-tuned orchestra, producing music that resonates harmoniously rather than cacophonously. Understanding this relationship fosters a greater appreciation for the engineering that underpins modern automotive design.

In the realm of vehicle diagnostics, troubleshooting does not end with the O2 sensor. Various components can interact and influence sensor readings, analogous to how one off-note can affect an entire symphony. Fuel injectors, air filters, and even spark plugs can contribute to variations in combustion efficiency, impacting how the sensor perceives the exhaust. Consequently, a thorough diagnostic approach assesses not only the oxygen sensor but also adjacent systems that could be affecting performance.

Regular maintenance of an engine can preempt many issues associated with O2 sensors. Replacing old or worn spark plugs, ensuring fuel injectors are functioning correctly, and maintaining clean air filters can mitigate potential deviations in sensor readings. Just as a musician sharpens their skills through practice, maintaining these components fosters an efficient, high-performing engine.

In conclusion, O2 sensor diagnostics and the normal voltage at idle represent a fundamental aspect of automotive maintenance. By understanding how these sensors operate within the broader context of engine performance, one can make informed decisions regarding their vehicle’s health. The symphony of combustion and emissions control plays on, with the O2 sensor guiding the performance narrative—a critical component ensuring that every note in the automotive concerto is played to perfection.