Pneumatic systems, often likened to the intricate workings of a well-orchestrated symphony, rely on a symphony of components—including air pumps, valves, and tubing—to create powerful, efficient movements. Much like a conductor guiding musicians, the proper wiring in these systems directs the flow of compressed air, activating machinery and enabling complex industrial processes. This article will walk you through the sedulous art of connecting pneumatic wiring to an air pump, ensuring your systems perform in harmonious unison.

To embark on this journey, we first need to understand the main characters in our pneumatic narrative. At the heart of the system lies the air pump, often referred to as the lungs of the operation. It converts electrical energy into compressed air, which acts as the driving force behind various mechanisms. The other cast members include the pneumatic actuators, valves, and control systems—each playing a pivotal role in managing the air once it’s been pumped. Connecting these elements requires not only technical know-how but also an understanding of the underlying principles governing pneumatic systems.

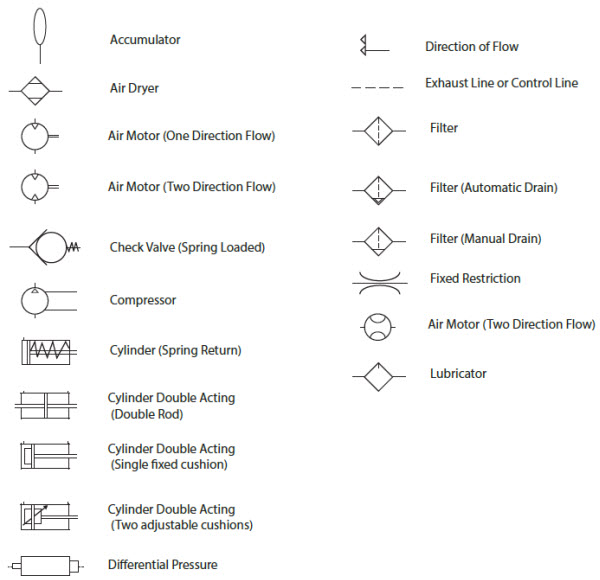

Before the act of connection, preparation is key. Begin by gathering all necessary materials: wires, connectors, pneumatic tubing, and tools such as wire strippers, screwdrivers, and a multimeter. Think of these items as your toolbox, each ready to assist you in crafting a masterpiece of pneumatic engineering. Additionally, consult the manuals of your air pump and related components to familiarize yourself with their specific wiring diagrams and operational requirements. This preliminary research lays the groundwork for a successful installation.

Once you have your tools and components, it’s time to dive into the wiring itself. Begin by ensuring that all components are de-energized—safety should always be your first act in any electrical endeavor. The wiring process can be likened to weaving a tapestry; each strand must be aligned correctly to create a cohesive and functional whole. Start by identifying the terminals on your air pump. Most pumps will have clearly marked connections for power and ground, which serve as the initiators of air flow.

To connect the power supply to the air pump, strip the ends of the wires using your wire strippers. Connect the positive wire to the designated terminal on the pump, ensuring a secure and firm fit. Next, connect the negative wire to the ground terminal. This connection serves as a return path for the electric current, much like a river flowing back to the ocean after feeding the surrounding landscape. Sprinkling in a touch of wire management, secure the wiring to prevent any potential wear or disconnection during operation.

Next, we must introduce the pneumatic valves into our setup. These valves function as the gatekeepers, dictating when and how much air is released to the actuators. Connecting the valves to the pump involves using pneumatic tubing, which must be cut to precise lengths to ensure a clean, leak-free fit. Think of these tubes as the veins through which compressed air will flow. Attach one end of the tubing to the outlet of the pump and the other to the valve’s inlet. This action requires a gentle but firm push, ensuring the tubing is seated entirely in the connectors. A little dab of lubricant can often ease the process, akin to applying oil to a well-used machine.

With valves in place, it’s time to connect the actuators. These components convert the compressed air into mechanical motion, resulting in the desired action—be it lifting, pushing, or rotating. The actuators will also require pneumatic tubing for their connections. The same meticulous approach to attaching tubing should be applied here. Once everything is connected, double-check to ensure each fitting is secure and there are no kinks or twists in the tubing that could impede air flow. This moment is akin to standing back and admiring the foundation of a grand structure; everything should be solid and properly aligned.

As our pneumatic wiring masterpiece begins to take shape, we approach the final stage of testing and troubleshooting. Re-energize the system and observe as air begins to flow through the lines. This is where you’ll want to employ your multimeter to check for continuity and ensure there are no short circuits that could spell disaster. Listen attentively for any unusual sounds—leaks can manifest as hissing noises, indicating points where air escapes instead of being directed where it’s needed. Like tuning a musical instrument, small adjustments can have profound effects on the overall performance.

Once tested, it’s time for a trial run. Activate the air pump and observe how the actuators respond. If everything flows smoothly, you can take a moment to appreciate the symphony you’ve created—the harmonious interplay of air and electricity now operates seamlessly as intended. Celebrate this small victory; it is the culmination of skill, knowledge, and a bit of artistry.

In conclusion, connecting pneumatic wiring to an air pump is more than just a technical task—it’s an endeavor steeped in precision and creativity. By understanding each component’s role and forging connections with care and ingenuity, anyone can successfully orchestrate a pneumatic system. As the air flows through the meticulously connected lines, remember: you are not merely activating machinery; you are bringing automation to life, breathing vigor into the processes that drive modern industry.