The topic of suspension systems often evokes curiosity among car enthusiasts and casual drivers alike. Amidst the myriad components that constitute a vehicle’s suspension, control arms play a pivotal role. This article will delve into the essentials of control arms, their functions, different types, and how many control arms can typically be found in a car.

At the heart of a vehicle’s suspension system lies the delicate balance between comfort and control. Here, control arms are instrumental in this equilibrium. These components connect the vehicle chassis to the wheel assembly, allowing for the necessary up-and-down motion while also providing lateral stability. Vehicles generally possess two types of control arms: upper and lower. While some designs may have only one upper arm or employ a single control arm, most standard vehicles feature a pair of both types on each wheel. As a result, a typical car would have four control arms at the very least, but this number can vary based on the suspension design.

The standard double wishbone suspension system incorporates two control arms at each wheel—one lower and one upper. This configuration ensures better handling and allows for a greater range of motion. This is particularly prominent in sports cars, where precision and responsiveness are paramount. In comparison, the MacPherson strut suspension—a popular choice in compact cars—usually employs a single lower control arm paired with a strut assembly above. This system simplifies construction, making it both cost-effective and lighter while sacrificing some degree of performance when compared to its double wishbone counterpart.

However, the fascination with control arms extends beyond mere numbers and types. One may ponder why the position and design of these control arms are critical in suspension systems. The geometry of the control arms influences how the vehicle handles during acceleration, braking, and cornering. This geometry plays a significant role in vehicle dynamics, particularly in how a car behaves during turns. A well-engineered suspension system mitigates body roll and promotes stability, allowing drivers to navigate twists and turns with confidence.

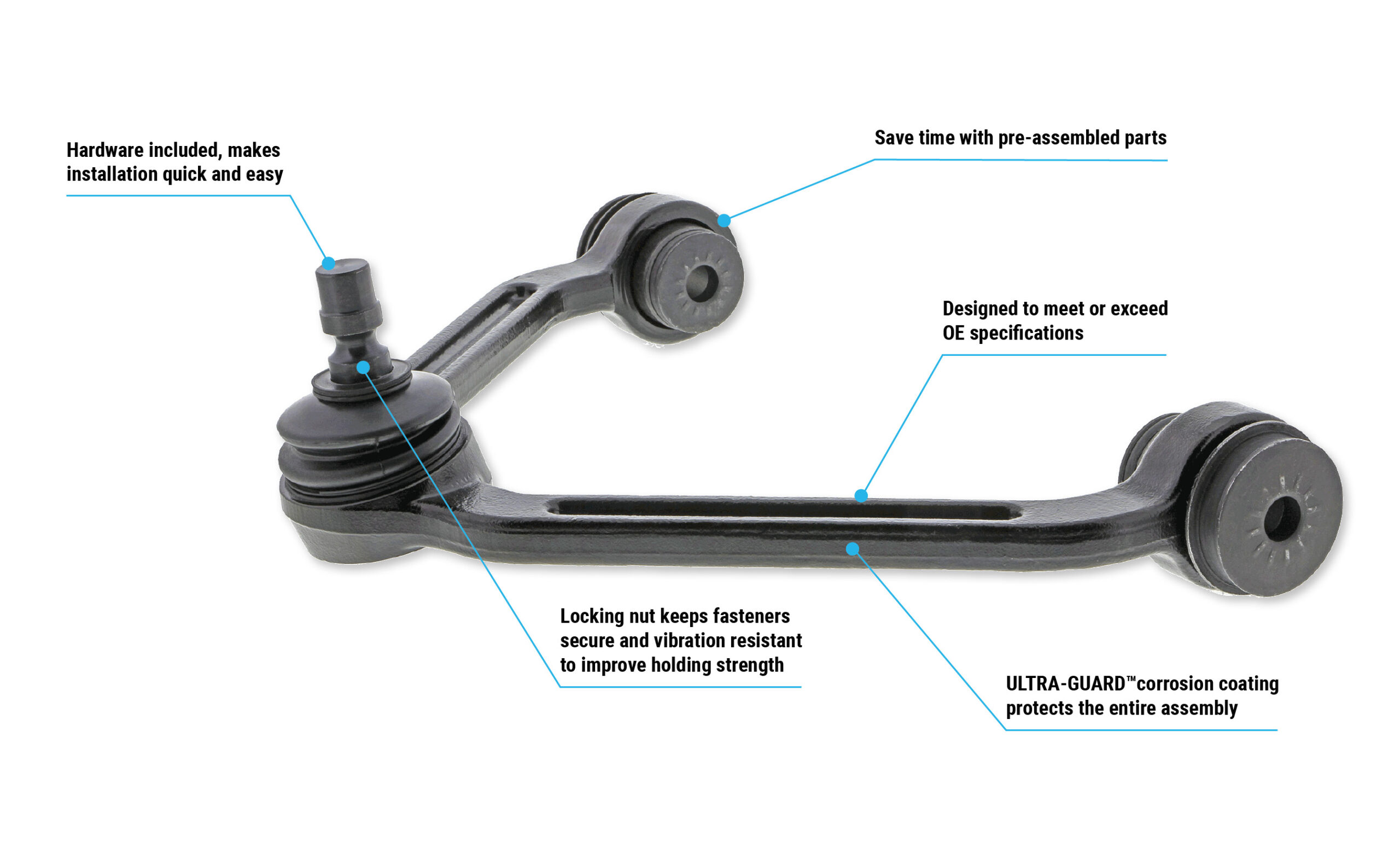

Control arms contribute significantly to the overall ride quality and handling performance of a vehicle. As the wheels travel over uneven terrain, control arms facilitate the necessary articulation required for keeping tires in contact with the road. This adherence maximizes traction, enhancing the driver’s ability to maneuver effectively. Furthermore, the quality of materials used for manufacturing these arms is paramount. Those constructed from high-strength steel or aluminum alloys provide increased durability and less weight, positively impacting performance and efficiency.

One must also consider the maintenance and servicing of control arms. Over time, bushings and joints may wear out due to constant motion and pressure. This deterioration can lead to significant issues such as steering misalignment, increased tire wear, and even compromised safety. Thus, regular inspections and timely replacements of worn control arms are advisable. Mechanics often recommend a comprehensive suspension check when performing routine maintenance to ensure all components, including control arms, are in optimal condition.

When discussing vehicle modifications, it is essential to highlight how aftermarket control arms can enhance performance. Enthusiasts often look to upgrade their suspension components for considerably improved handling characteristics. Performance-oriented control arms may feature improved geometry, adjustable settings, and robust materials tailored for racing or spirited driving. Such modifications can result in enhanced precision during cornering and reduced weight for agile maneuvering.

Interestingly, the fascination with control arms often leads to discussions on riding styles and vehicle designs across different manufacturers. Luxury vehicles and high-performance models frequently incorporate advanced suspension technologies that innovate upon traditional designs. For instance, adaptive suspension systems utilize control arms but apply intricate adjustments through electronic dampers that adapt to driving conditions. This offers drivers a seamless blend of comfort and sportiness, further blurring the line between luxurious cruise and exhilarating performance.

As the automotive industry leans into advanced technologies like autonomous vehicles, the role of control arms may evolve. With the integration of sophisticated sensors, it is conceivable that the future of suspension systems could incorporate real-time data analysis to modify suspension behavior instantaneously, relying on the control arms as foundational components of this dynamic architecture.

In essence, control arms are not just mere mechanical brackets; they are a critical nexus of engineering and artistry in automotive design. They exemplify the meticulous attention to detail and the pursuit of automotive perfection. Driving enthusiasts often recognize this, leading to a compelling interest in understanding the intricate workings of their vehicles’ suspension systems. Not only do these components significantly affect handling performance and comfort, but they also embody the heart and engineering precision behind a vehicle’s ability to glide over the asphalt.

So, as you traverse through the winding roads or cruise the highways, consider the unsung heroes of your car: the control arms. Their articulation allows for a smoother ride, better control, and a fulfilling driving experience. Despite being hidden beneath the vehicle, control arms silently collaborate with countless other components to ensure a harmonious balance between safety and performance.