When was the last time you checked your vehicle’s suspension system? One critical component that often goes unnoticed is the ball joint. How can you tell if a ball joint is bad? This is more than just a rhetorical question; it can present a significant challenge for vehicle owners who may not be well-versed in automotive mechanics. Understanding the symptoms of a failing ball joint can save you from potential hazards on the road, as well as from hefty repair bills down the line. In this article, we shall explore the functionality of ball joints, the signs that indicate failure, and the implications of driving with defective joints.

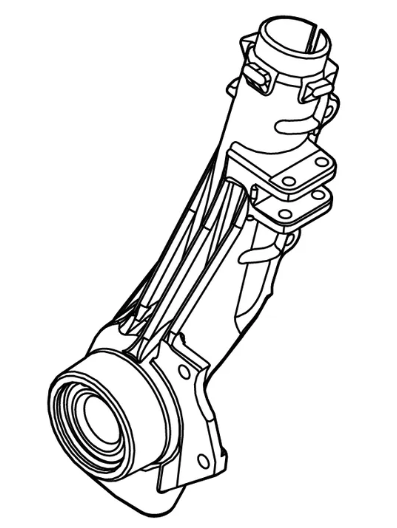

A ball joint is a pivotal component of your vehicle’s suspension system. It functions similarly to a human shoulder joint, allowing for smooth movement and rotation. Ball joints connect the vehicle’s control arms to the steering knuckles. They endure continuous stress every time you drive, especially when navigating bumps, turns, or uneven surfaces. Hence, understanding how to properly assess their condition is essential for maintaining vehicular safety and performance.

Now, let’s delve into the telltale signs of a failing ball joint. One of the most noticeable indicators is the presence of unusual noises. Have you ever heard a creaking, popping, or grinding sound while turning or driving over bumps? These noises can be a clarion call from your vehicle, hinting that your ball joints may be worn out. Such sounds are often attributed to excessive movement or wear within the joint’s assembly, signaling that the integrity of the connection is compromised.

In addition to auditory cues, visual inspections can be enlightening. When examining the suspension components, look for any signs of physical damage or unusual wear. Frequently, a degraded ball joint might exhibit visible play or movement when you attempt to wiggle it. An easy method to check this is to lift the vehicle and grasp the tire at the 12 o’clock and 6 o’clock positions, then try to rock it back and forth. If there’s excessive play, it may be time to consult a professional.

But wait, there’s more! The importance of regular maintenance cannot be overstated. Keeping a vigilant eye on your vehicle’s suspension can mitigate potential issues before they escalate. This includes routine inspections and maintenance of your ball joints. A qualified mechanic can employ various techniques—including the use of a ball joint press—to evaluate the joints’ condition accurately. Prevention is always better than cure, so make it a habit to have your suspension system checked during every regular service appointment.

Another critical aspect of ball joint failure is the potential for additional vehicular issues. When a ball joint degrades, it may also affect other components in the steering and suspension systems. A single bad joint can alter the alignment and handling of the vehicle, which may lead to uneven tire wear. Imagine investing in a new set of tires only to have them wear out prematurely due to unresolved issues in your suspension system. This cascade of problems is a clear argument for the importance of addressing ball joint issues swiftly.

Driving with bad ball joints can lead to severe consequences. The most alarming risk is the potential for complete joint failure. If a ball joint breaks while driving, it can cause a loss of control over the vehicle, potentially leading to accidents. This risk underscores the necessity of immediate assessment and repair upon detecting any anomalies in your ball joints.

When it comes to replacing ball joints, it is crucial to choose high-quality parts. Opt for components that are engineered to meet or exceed the original equipment specifications. While it may be tempting to select cheaper alternatives, lower-quality components often fail sooner, ultimately costing you more in the long run. Look for reputable brands and consider consulting your mechanic about the best options tailored to your vehicle.

Moreover, consider the material of the ball joints. The most common materials used include steel and thermoplastic elastomers, each with its advantages and drawbacks. Steel joints have superior durability but may corrode over time if exposed to harsh environmental conditions. Conversely, thermoplastic elastomer joints can offer enhanced flexibility but may not withstand extreme stress. Assessing the environmental conditions in which you regularly drive can guide you in selecting the appropriate material for your ball joints.

Interestingly enough, a successful inspection and maintenance routine can also enhance your vehicle’s overall performance. Many drivers report an improved ride quality and handling after addressing ball joint issues properly. Vehicle performance is directly related to suspension integrity; thus, diligent attention to these components not only contributes to safety but can also lead to a more enjoyable driving experience.

Ultimately, by gaining insight into how to identify a bad ball joint, you arm yourself with knowledge that fosters foresight and preventative action. You may not be a mechanic, but you can still play an active role in ensuring the safety and longevity of your vehicle. Your vigilance can help you avoid potential pitfalls on the road and keep you safe in unpredictable driving conditions. So, the next time you hear an odd noise or feel a strange movement in your vehicle, ask yourself: Is it time for a suspension check? The answer could be critical for your vehicle’s health and your own safety.