Torque is a fundamental concept in mechanics, influencing how we tighten bolts, secure fixtures, and ensure the proper operation of machinery. Understanding torque and its appropriate measurements is vital for various fields, from automotive maintenance to construction. In this article, we’ll explore the intricate relationship between inch pounds and foot pounds, with a specific focus on converting 15 inch pounds to foot pounds. This guide will delve into the definitions, applications, and conversion methods while providing insights into best practices for torque measurement.

To begin, let’s clarify what torque is. Torque, often termed as rotational force, signifies the degree of force causing an object to rotate around an axis. It is generally expressed in units of pounds-force (lb-ft or lb-in). Typically, foot pounds (ft-lb) are used for larger measurements, while inch pounds (in-lb) are common for more precise or smaller-scale applications. This distinction is essential in various scenarios, such as automotive repair, where precise torque specifications are crucial for ensuring vehicle safety and performance.

Understanding the need for conversion arises when different tools and machinery use distinct torque measurement units. For instance, a mechanic might use a torque wrench calibrated in inch pounds, while the specification for the bolt states a requirement in foot pounds. Here, the conversion becomes necessary. But how do we perform this conversion effectively?

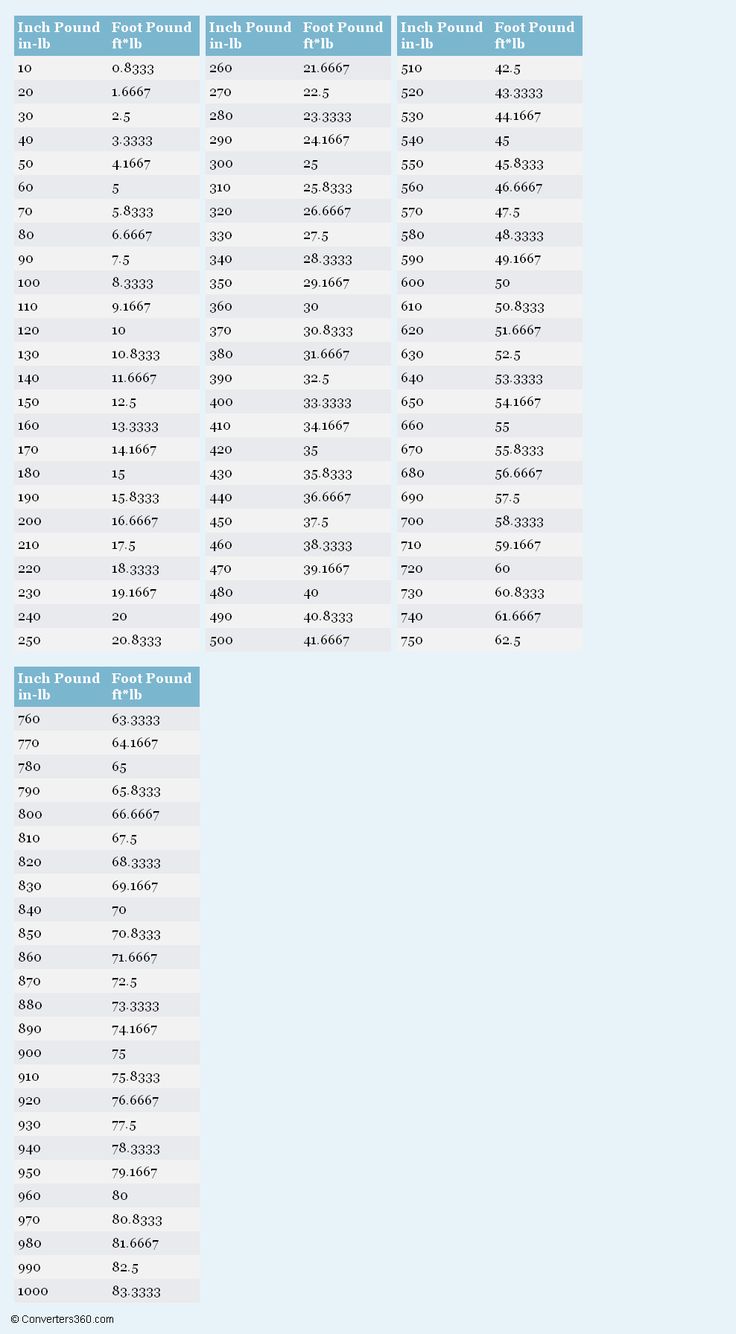

To convert inch pounds to foot pounds, one must bear in mind the fundamental relationship between the two units. There are 12 inches in a foot, which introduces the conversion factor. To convert inch pounds to foot pounds, simply divide the number of inch pounds by 12. Therefore, the conversion formula can be expressed as:

Foot Pounds = Inch Pounds ÷ 12

Applying this formula to our example of 15 inch pounds yields:

Foot Pounds = 15 ÷ 12 = 1.25

This means that 15 inch pounds is equivalent to 1.25 foot pounds. This conversion is straightforward, yet the practical implications are profound, especially when one strives to achieve precise torque settings.

While understanding conversions is vital, it is equally important to recognize the contexts in which these measurements are utilized. In mechanical applications, the incorrect torque can lead to disastrous consequences. For instance, under-torqued bolts may lead to loosening during operation, while over-torqued bolts run the risk of stripping threads or even causing materials to fracture. Thus, reliable torque specifications and conversion knowledge become invaluable assets in the toolkit of any technician or tradesperson.

Beyond the mechanics of conversion, the tools employed for measuring torque are equally critical. Torque wrenches, whether they are beam, click type, or electronic, are designed to provide the user with tactile feedback when the desired torque has been reached. Familiarizing oneself with these tools is imperative. For instance, using a click-type torque wrench requires a clear understanding of the settings for both inch pounds and foot pounds to ensure accuracy.

Furthermore, the torque application process necessitates a systematic approach. It is advisable to apply torque in stages, gradually increasing it to the specified level rather than attempting to reach the target in one swift motion. This method not only ensures consistency but also reduces the likelihood of mechanical failure. When dealing with multiple fasteners, following a specific sequence—often referred to as a torque sequence—can help distribute force evenly, enhancing the integrity of the assembly.

Another factor to consider is the material of the components being fastened. Different materials exhibit varying properties that can affect the torque application. For example, softer metals require lower torque values compared to harder materials to prevent deformation. Understanding these nuances helps in selecting the appropriate torque level and conversion for any given task.

In addition to the mechanical aspects, safety cannot be overlooked. When working with torque tools, ensuring that personal protective equipment (PPE) is worn is essential for safeguarding against potential injuries. Similarly, keeping the working environment tidy and free from hazardous materials contributes to a successful workflow.

In summary, converting 15 inch pounds to foot pounds is a simple yet significant task that underscores the importance of torque in various applications. Knowing how to convert units quickly can save time and reduce errors, ultimately leading to greater efficiency in mechanical work. By mastering the relationship between inch pounds and foot pounds and employing best practices in torque measurement, individuals can significantly improve their effectiveness and outcomes in their respective fields.

Remember, whether you are an amateur DIYer or a seasoned professional, mastering torque conversion and its applications enhances both skill and confidence. With the right knowledge, tools, and practices, you can ensure that every bolt is tightened to perfection, paving the way for successful mechanical endeavors.