When it comes to the world of automotive transmissions, the 4L80E stands out as a technological marvel, revolutionizing how power is transmitted from the engine to the wheels. This automatic overdrive transmission, widely celebrated in trucks, vans, and performance vehicles, offers an intriguing blend of durability and efficiency. In this comprehensive overview, we will delve into the intricacies of the 4L80E, exploring its features, performance, and maintenance considerations.

Understanding the 4L80E Transmission

The 4L80E was designed by General Motors, engineered to endure demanding conditions while providing enhanced control over gear shifting. Characterized by its four forward gears and a single reverse, this transmission gives it the ‘4L80E’ designation—where “4L” indicates its manual shifting capabilities, “80” refers to its capacity to handle 800 lb-ft of torque, and “E” signifies its electronic control. This transmission first came into widespread use in the early 1990s and has since become prevalent in a broad array of vehicles from heavy-duty trucks to performance-oriented muscle cars.

Key Features and Innovations

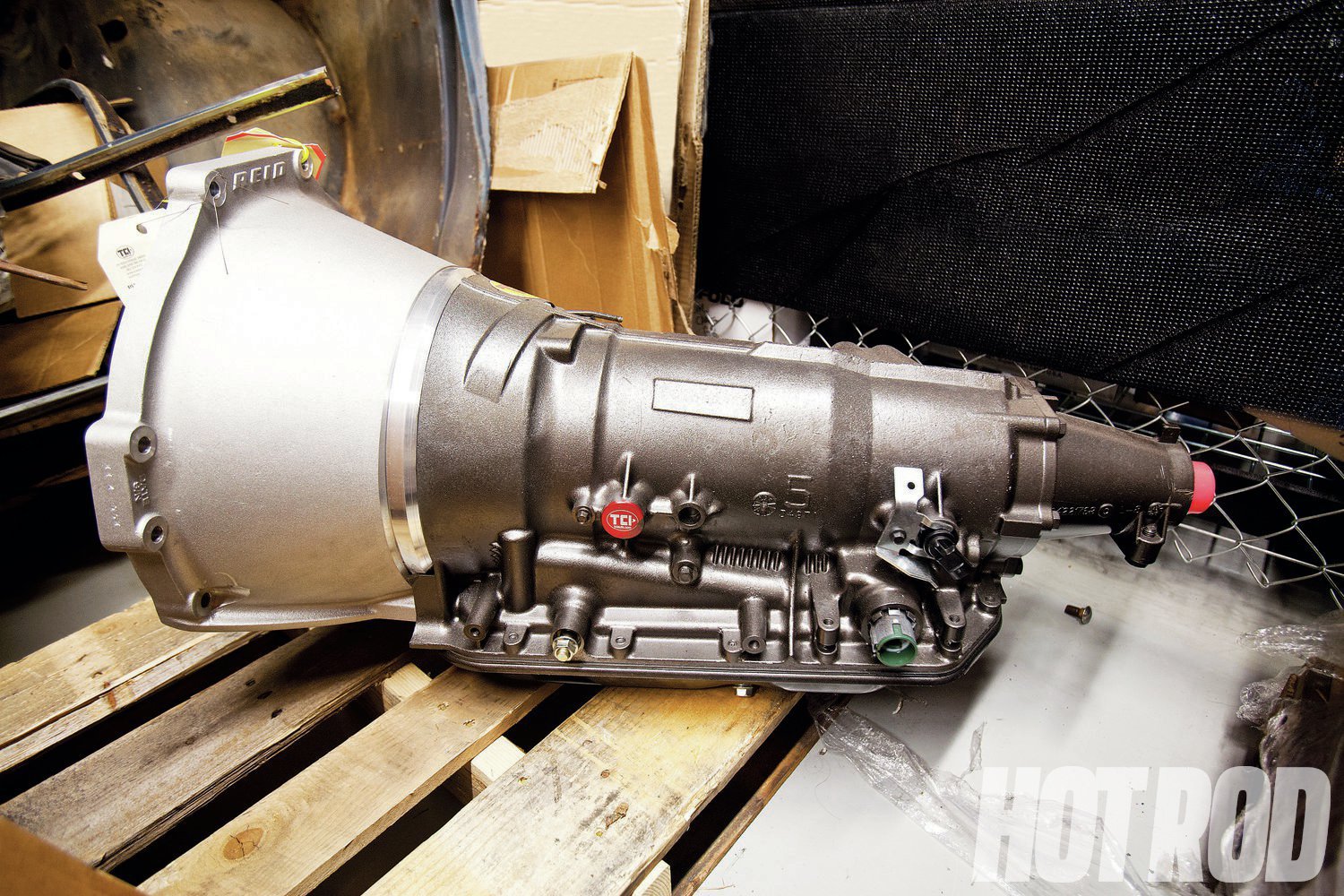

One of the defining features of the 4L80E is its robust construction. This transmission utilizes a heavy-duty housing made of aluminum, which significantly reduces weight while maintaining toughness. Internally, the 4L80E employs a sophisticated hydraulic system with electronic controls, allowing for seamless gear transitions and improved responsiveness. The incorporation of a torque converter lock-up function optimizes fuel efficiency by eliminating slip, thereby enhancing torque transfer when cruising at higher speeds.

Performance and Applications

The versatility of the 4L80E makes it a popular choice across various vehicle types. In the realm of heavy-duty applications, it is the go-to transmission for medium-duty trucks and large SUVs due to its unparalleled torque capacity. High-performance enthusiasts favor the 4L80E for its adaptability in custom builds, particularly in applications using powerful LS engines. Its ability to handle power outputs exceeding 600 horsepower without compromising reliability is a testament to its engineering prowess.

Moreover, the 4L80E is lauded for its adaptability to different tuning options. Whether it’s used in standard driving conditions or extreme motorsport scenarios, custom calibrations can optimize shift points and torque management, tailoring the driving experience to the preferences of the operator.

Installation Considerations

Installing a 4L80E transmission isn’t merely a matter of dropping it into place; it requires precision and attention to detail. Compatibility with the engine and other drivetrain components must be confirmed. Many vehicle owners often opt for an aftermarket transmission controller when integrating the 4L80E into non-GM vehicles. This is critical for managing electronic controls and ensuring smooth operation.

Additionally, the installation of a transmission cooler cannot be overstated. Given the heavy-duty nature of the 4L80E, it’s vital to maintain optimal operating temperatures, especially in performance applications. Upgraded cooling systems can prolong the lifespan of the transmission and enhance its functioning.

Maintenance and Longevity

Another factor contributing to the reliability of the 4L80E is the importance of checking and adjusting the transmission’s linkage and throttle cable regularly. Improper adjustments can lead to erratic shifting and potentially catastrophic failures. Close vigilance on the health of the torque converter is also advisable, as any failure in this component can lead to significant damage to the entire transmission.

Troubleshooting Common Issues

Even the most well-engineered transmissions are not entirely immune to issues. Owners of the 4L80E should be aware of some common signs of trouble. Slipping gears, harsh shifting, or even transmission overheating are indicators that something may be amiss. Keeping a close eye on the transmission fluid level and condition can preempt many potential issues.

If diagnostics reveal more severe concerns, such as internal wear or damage, professional assessment may be necessary. Skilled technicians can often pinpoint problem areas with ease, but being proactive can often save vehicle owners both time and money.

The 4L80E in Modern Builds

The legacy of the 4L80E continues to thrive in the realm of modern custom builds. Many enthusiasts opt to swap this transmission into classic muscle cars or kit cars, seeking the balance of vintage styling with contemporary reliability. The adaptability of the 4L80E, along with its robust performance metrics, ensures it remains a favored choice in automotive engineering circles.

From off-road vehicles to high-performance drag racers, the capability of the 4L80E allows for an expansive range of modifications and upgrades. Enhanced shift kits, dual servo kits, and increased pressure valve bodies can transform the driving experience, catering to the increasingly demanding standards of modern performance.

Conclusion

The 4L80E transmission is more than just a component in a vehicle; it represents the culmination of innovative engineering and user-centric performance. Its diverse applications, coupled with its reliability and adaptability, cement its position as a staple in both everyday driving and high-powered builds. Whether you’re a casual driver or a performance enthusiast, understanding the intricacies of the 4L80E can empower you to make informed decisions about your vehicle. Embracing the capabilities and potential of this remarkable transmission will undoubtedly enhance your driving experience, regardless of the car you choose to drive.